On October 2, on the MP-156 site of Bab Buhasa Oil Area, Bab Buhasa AiP5 production project of CPECC Gulf Region Company, bulldozers were roaring and earthmoving works were in full swing. "The CPECC team is a reliable partner with strong execution, verbal commitment and results in action." Wael Saleh Almessabi, Vice-president of ADNOC Onshore, spoke highly of the CPECC team's project management and schedule control capabilities.

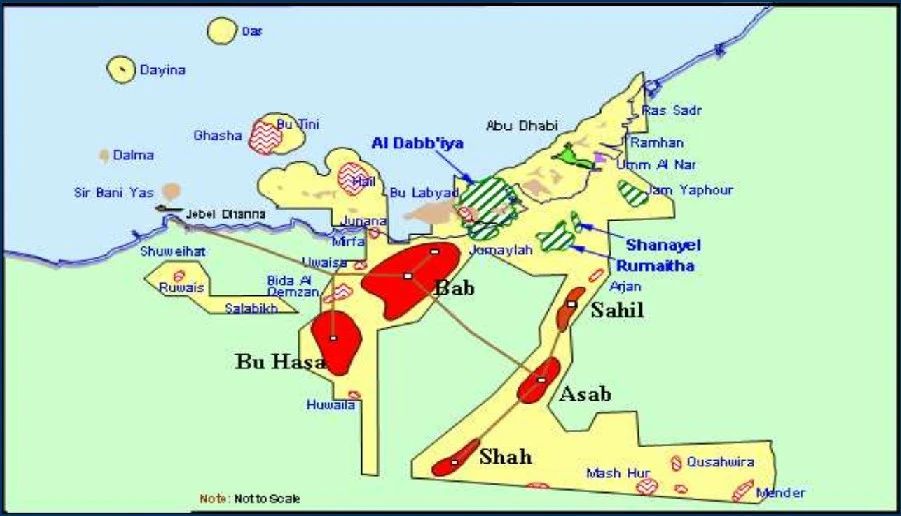

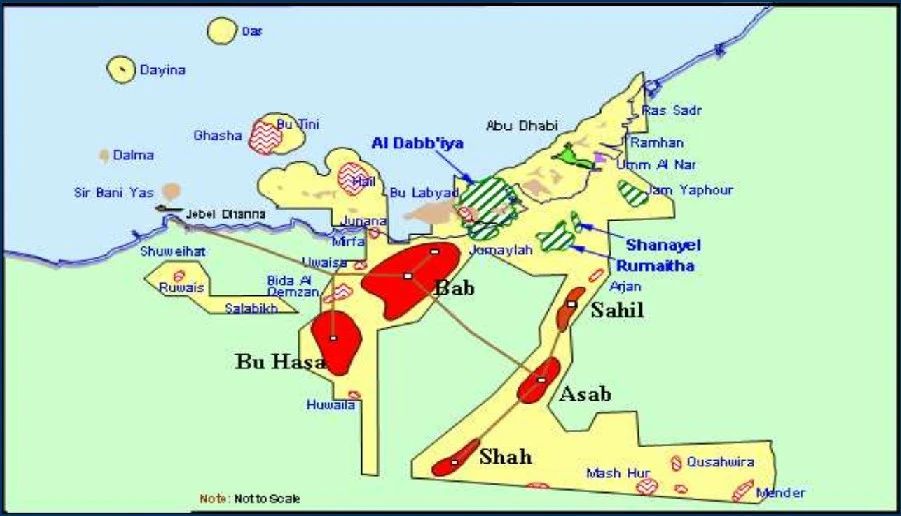

The Bab Buhasa AiP5 production project undertaken by CPECC is ABU Dhabi National Oil Company's (ADNOC) ultra-large surface oil field EPCM project, which is also its breakthrough attempt in the field of AI numerical control. The project covers 3,980 square km in Bab and Buhasa oilfields, including 80 ADNOC Onshore Bab and Buhasa oilfields, the renovation and expansion of nearly 600 oil, water and gas Wells and 1,000 km of new long haul pipelines. Once operational, it will increase production by 116,000 BPD at Bab and 141,500 BPD at Buhasa.

"After the project is completed, we will be able to remotely control Wells hundreds of kilometers away from the central processing station." Mohammed Saleem Abbasi, regional construction manager for the AiP5 project inBuhasa, Gulf Region Company.

Build and share to play a "precise card"

As the centerpiece of ADNOC's P5 plan to increase production to 5 million BPD by 2027, the AiP5 project is based on the new EPCM project model, actively communicating with the owner, constantly exploring innovation, and improving as it is implemented.

Facing the great challenge of full production in 2027, the AiP5 project team accurately grasped the needs of the owners, proposed an innovative concept of "first oil", and worked out a phased and batch production plan with the owners, which not only realized the operation of some Wells more than one year in advance, and created additional economic benefits for the owners. It also has laid a solid foundation for the acceleration of the AiP5 project.

The EPCM model pays more attention to the flexibility and adaptability of the project, and the project team is not only the executor, but also the "technical consultant" who covers the design, procurement, construction and management.

Drawing on CPECC's rich experience in construction organization, the AiP5 project team proposed to divide the construction subcontracting into 9 main parts and select large and powerful subcontracting units with deep qualifications to cooperate. While the owner initially preferred multiple subcontractors to reduce costs, as the project model review and procurement work progressed, the owner gradually recognized the complexity of interfacing with multiple subcontractors and agreed to streamline subcontractors. This decision not only simplifies the business bid evaluation process, improves the overall progress of the project, but also strengthens the control of the project quality.

Strong foundation and solid foundation Draw “concentric circles well”

Compared with EPC projects, EPCM projects lack the detailed guidance of the FEED (Front-End Engineering Design) stage, which is like drawing on a blank sheet of paper and stimulating creativity with only a few keywords. ADNOC's high requirements for process design, especially process simulation and hydraulic calculations, have created unprecedented challenges for the project team.

In order to avoid the adjustment of the design stage affecting the subsequent procurement and model review progress, the project team set up a detailed design team led by the process office of the Beijing Branch to quickly start the preliminary process design, summarize and share experience in time, and accelerate the adaptation process of the new ADNOC Standard (AGES). In addition, the AiP5 project for the first time tried to conduct commercial bid evaluation and order some materials simultaneously when the design accuracy reached 50%, and continued to improve the design drawings and add materials successively. This innovative working mode not only meets the requirements of precision in design, but also improves the efficiency of project operation.

In Bab and Buhasa, two old oil fields that have been in operation for more than 60 years, the AiP5 project faces particularly difficult challenges. The laying of 1000km new long distance pipeline not only solve the technical problems such as large line span and many old pipe lines crossing, but also deal with the interference of external parallel projects. In order to improve efficiency, the project team and the Beijing Branch studied the ADNOC construction procedure documents in depth, identified the key nodes requiring the intervention and coordination of the owner's interface department, and prepared a set of standard flow chart that clearly planned the work content and completion time of each link, and confirmed it with the owner, subcontractors and external parallel project parties. Turn passive work into active collaboration.

"This experience has been both a challenge and a valuable experience, and we now have the ability and confidence to tackle any project or design challenge." Beijing branch Aip5 project design deputy manager Wang Jinjie firmly said.

Gather strength and transform to play the "main melody"

With the rapid development of the ADNOC P5 production increase program, the manpower and material resources in the UAE market are becoming increasingly tight. In order to gain an edge in the fierce market competition, the owner required the AiP5 project team to complete the arduous task of compiling the entire EPCM project pre-planning package within two months. This includes not only project investigation, risk analysis, cost estimation, but also design, procurement, construction and plan management, which runs through the entire project execution cycle, and the workload is huge.

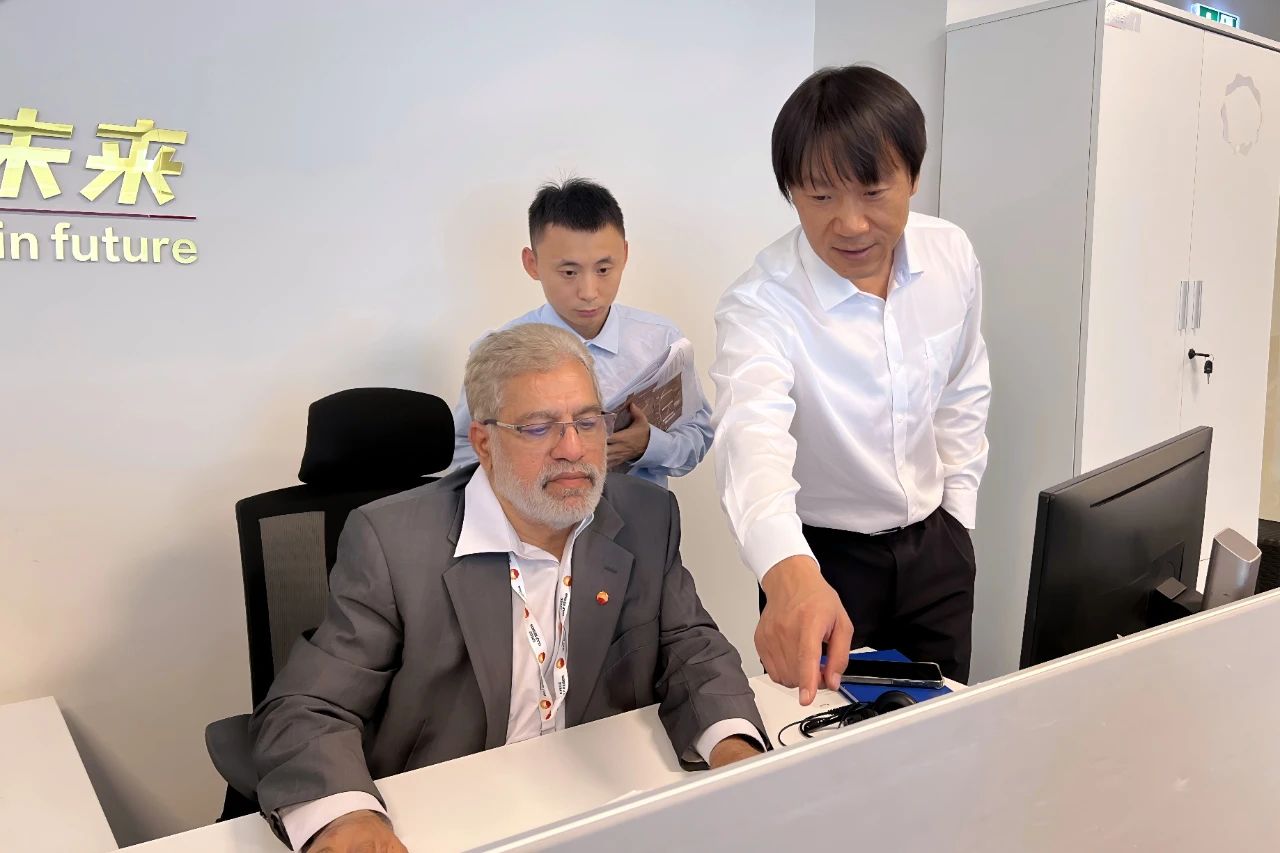

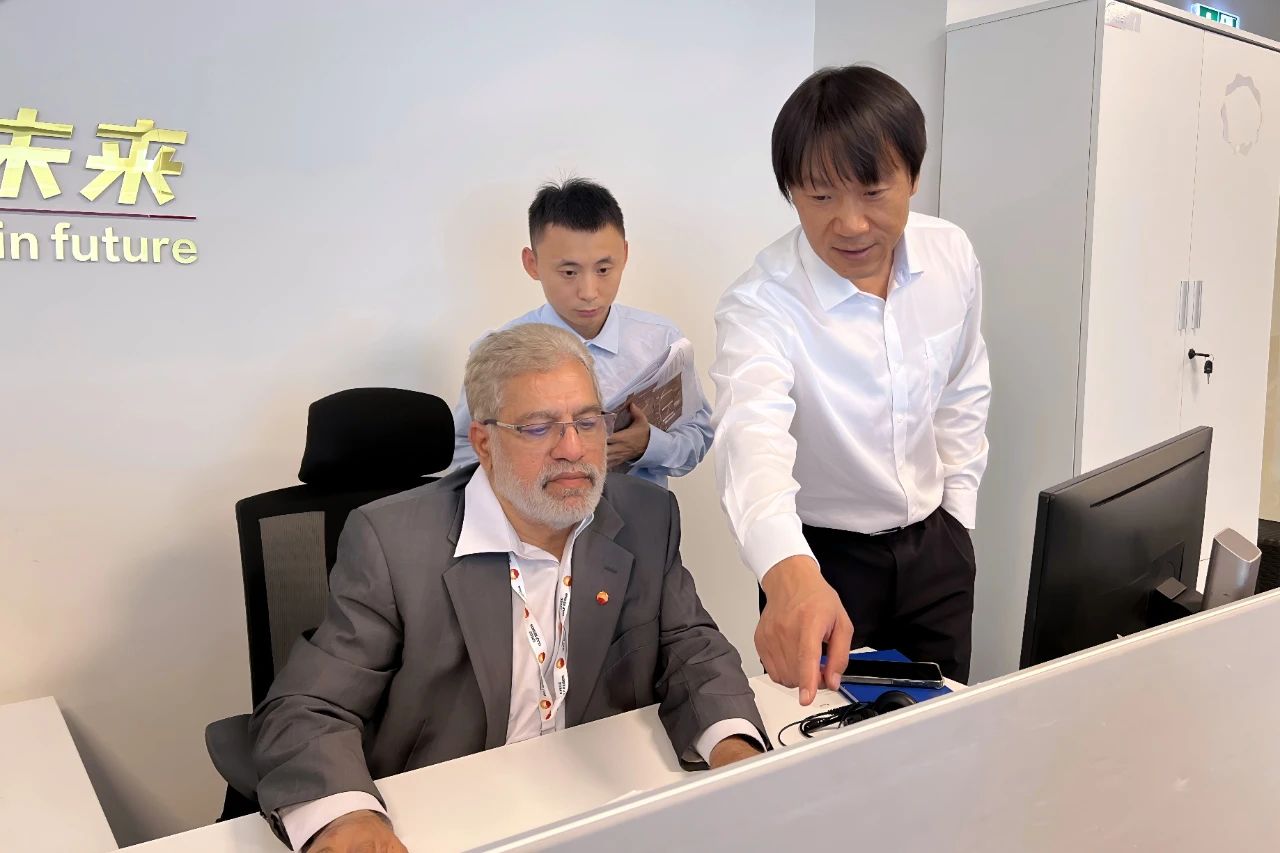

Faced with the challenge, Zhang Fan, manager of AiP5 Project Control Department, led three foreign employees to work together, discuss the details of the plan with the owner during the day, and work overtime at night to adjust the plan package. Within 60 days, more than 2,600 pages of the plan package were completed according to the node. "The owners were amazed at how efficient our team was, and the fact that four of us did what would have taken at least 10 people to do was a huge boost for our entire team." Zhang Fan is full of praise for each member of the project team, he said proudly, "Always ahead of the task, is the firm belief of our team."

Kaleem Aziz, a Pakistani national, has worked for several international companies and joined CPECC in 2017. With his outstanding professional ability, he serves as the interface Manager of Aip5 project. He is busy communicating with people from different countries and different business areas every day to organize and coordinate complex interface interchanges. In the face of endless difficulties on the scene, Kaleem said cheerfully: "Every time I successfully solve the problem, I feel very proud." He compared the Chinese team to a big family, which is closely united and working together to achieve goals.

Over the past year, AiP5 project has not only completed the contract milestone several times ahead of schedule, but also won the trust of the owner with high quality and high standards, and the scope of project work has been extended four times.

From an initial team of a few dozen people to an international team of more than 500 employees from more than 20 countries, AiP5 project has opened up a new situation in the reform, The theme of harmonious development of "respect, equality, openness, inclusiveness and integration" has been played overseas, and built a team full of identity, belonging and cohesion. In promoting transformation and upgrading and exploring the road of digital empowerment, we continue to move forward.

Hello! I am the Oriental ChatBot. Just let me know what you need, and I will be happy to help.

Hello! I am the Oriental ChatBot. Just let me know what you need, and I will be happy to help.

Choose your Language preference.

Choose your Language preference.